Modular Homes aren’t earthquake-safe by definition, however, prefabricated buildings tend to be more resistant to Earthquakes than conventional construction. In fact, since each module of the modular home is manufactured in a factory and transported to the site where it is going to be assembled, its frame is designed in order to ensure the structural integrity of each one of these modules during transportation. Meaning, each module is designed and self-stabilized, taking into consideration the vibration to which it is exposed during the shipping process, a tremor similar to that one of an earthquake.

Some modular homes are specifically designed and built to withstand stronger or more damaging earthquakes and need to take into consideration two very important aspects:

- Earthquake resistant Materials

- Earthquake resistant structure design

Taking these two factors into consideration definitely ensures an Earthquake-safe home but it will of course impact the way the modular home looks like. Therefore, it is important to know what are our own personal needs when it comes to Earthquake proofing our modular home in order to avoid measures that aren’t necessary.

Understanding Earthquake-proof Homes

All homes, being modular or build on-site, are constructed following the requirements specified in their localized building code. The strictness of these regulations depends on the Earthquake risk of the area and, very important, following the building code doesn’t entail an earthquake proof home. For example, the expected Earthquake performance of buildings designed to the California Building Code states that “The California Building Code is a minimum requirement intended to protect life safety and prevent collapse. It allows damage, which means buildings may not be habitable or functional after a moderate or large earthquake.” [1] Therefore, any home designed following these minimal requirements stated in the building code will ensure a basic life protection based on the Earthquake expectations in the area.

But in most locations, the fact that a home is build following these regulations doesn’t necessarily classify it as an earthquake-proof Home. Engineers have been researching solutions to improve the homes´ resistance to earthquakes for the past 7 decades [2] and today are working on developing innovative technologies such as the Japanese Air Danshin’s system [3], an airlift system capable of raising the whole house when the tremors are detected by sensors and the whole building is kept floating in the air until temblor stops [4]. But a part of these science fiction looking discoveries, the increasing understanding of the seismic forces and the building behaviour during the tremors, helped architects, engineers and builders reduce structural damage by choosing the right materials and design.

What does an Earthquake safe modular home look like?

Earthquake resistant materials

Every material has different qualities that will make it more or less resistant to earthquakes. Therefore, the materials chosen to build a modular home will be decisive on the behaviour of the house during an Earthquake. The most common materials used to build modular homes are wood, steel and concrete. Those materials with a better resistance to Earthquakes are light but also ductile, meaning that the material can undergo some deformation without losing toughness or breaking. A great example of a ductile material is steel since even though it is strong, it can bend without breaking [5]. When the building materials aren’t ductile but brittle, the horizontal forces caused by the earthquake tremors easily break them. Concrete, on its basic form is very strong and can support a lot of weight, but it easily breaks.

- Steel is a very common material in modular homes and it can be used both as support frames or even as the bulk of the building as it is in shipping containers [5]. Steel is a very good material to use in an Earthquake resistant modular home since it is low weight, ductile and strong. Structural steel allows the buildings to bend without breaking since it has the ability to undergo large deformations and tension. [6]. This characteristic allows steel to dissipate the energy from the tremors: as the building shakes, structural steel “dances” with it reducing the impact. Since Modular Homes are built in a factory and shipped to the site on a truck, it is common to use materials such as structural steel since they self-stabilize the module.

- Concrete together with bricks and stone is brittle and heavy. Therefore, on its most basic form it is not a good choice for an Earthquake resistant modular home. However, concrete can easily gain ductility when reinforced with steel and today we can easily modify its properties by adding additives such as graphene oxide, which reduces its weight and improves its resistance [7]. Even Japanese traditional wooden houses have today been replaced by reinforced concrete buildings designed based on seismic engineering and are highly resistant to earthquakes [8]. Therefore, concrete by itself isn’t Earthquake resistant, but we can easily engineer a concrete material that is, so it is possible for a modular home to be built with reinforces concrete.

- Wood is another material that is commonly used in modular homes, both as timber or as panel systems. In its natural form, is both flexible and light which makes it a great material to use in an earthquake-proof modular home. Timber however, even though is ductile is brittle. These qualities make it resistant to Earthquake to some extent since when exposed to the tremors it bends to avoid building stress [6]. Unfortunately, houses made with timber wood can collapse in strong Earthquakes. In Japan, “traditional wooden buildings have been evaluated based on seismic engineering, and this revealed that although traditional construction methods are in part based on seismic engineering, many aspects are not” [5].

Today though, wood materials have evolved and we have engineered wood into composites such as cross-laminated timber (CLT), glued laminated lumber (GLULAM), and laminated veneer lumber (LVL), which increases the ductility and flexibility of wood while reducing its brittleness designing a wooden material with properties that are even comparable to steel [5].

Earthquake resistant structure design

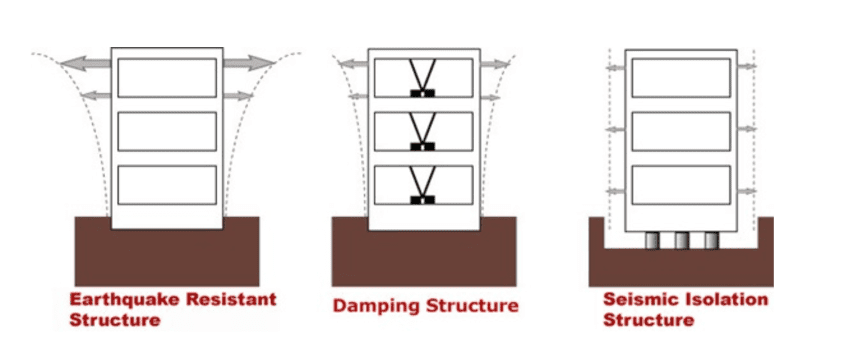

An Earthquake resistant modular home will be built with materials capable of absorbing the seismic energy, but to increase its resistance, taking care of the structure design is of great help [8]. There are basically 3 ways to Earthquake-proof a building structure depending on the modular homes´ design:

- Detached modular home: when our home is designed as a single unit and it is not attached to its neighbours the most efficient Earthquake-proof structure is an Earthquake Resistant Structure (Fig.1)which “allows the main building structure, namely, posts, walls and floors to absorb seismic motions” [9]. This design requires from a main structure that is very flexible, using ductile materials and from a secondary structure that Rigidizes some part of these first structure to control deformation and prevent collapse [9]. This kind of structure design will allow the house to sway quite a lot during the tremors but come back to its original position as soon as the earthquake is over.

- High-rise Buildings: while we will rarely encounter single family modular-homes designed as high-rise buildings, there are multiple examples of Multi-Storey Prefabricated Housing Modular Buildings with a high resistance to Earthquakes such as the multi-storey apartment building “Little Hero” in Melbourne, Australia [10]. In these situations, we can use a Seismic Isolation Structure (Fig. 1), a tremor-absorbing device such as dampers or springs placed in the foundation in order to isolate the tremors and block them from reaching the building [9]. The building will notice still a horizontal motion but it will be reduced “anywhere from ½ to 1/3 (less than half) when compared to earthquake resistant structure” [9].

- Any kind of Modular Home can benefit from a Damping Structure (Fig. 1),which in order to absorb the tremors uses damping walls. These damping systems can absorb the vibration using an absorbing material (passive method) or can be more complex and absorb this energy with the use of electricity and sensors (active method) [11]. This method is more effective but also more expensive and requires a large transformer. This kind of structure can reduce the seismic intensity up to 70-80% [9]

Unlike on-site constructions, modular homes are built per parts, every module is built separately and put together afterwards. This fact improves the performance of the building throughout the Earthquake since every part can be placed leaving a small separation between modules. And Earthquake resistant home is more flexible, and allowing each part of the building to move separately by leaving a joint or separation between these parts improves its resistance in front of Earthquakes [12]

How much should you Earthquake-proof a Modular Home?

There is a strong awareness on Earthquake Engineering since 1984 [13] that has established some minimal requirements into every Building Code in order to ensure life protections. Those locations with a very low Earthquake risk, in general can state that any Modular Home being build today is Earthquake safe since, as any other construction, they are obliged to follow the building code regulations and those contemplate an Earthquake risk. Since the modular home is built considering the tremors of the shipping, it is naturally Earthquake safe, especially in areas where Earthquakes are rare.

Other locations with a higher risk of very destructive Earthquakes such as Japan, Chile or California, even though their building code is a lot stricter in terms of Earthquake protection, any modular home won’t necessarily be considered earthquake safe unless specified by the manufacturer. In this cases, the house will be constructed with materials that are highly ductile and strong and most likely will adopt one of the structure strategies to ensure its resistance.

Even if modular homes aren’t Earthquake safe by definition, unless built for that purpose, any modular home build today is constructed following the safety measures established by its location and will therefore protect the life of its occupants. Due to the nature of the building process of modular homes, in most cases their resistance to earthquakes is higher than on-site homes.

References

- Expected Earthquake performance of building designed to the California building code State of California Seismic Safety Commission. https://peer.berkeley.edu/sites/default/files/peer2019-05_ssc19-01.pdf

- Lee W., Kanamori H., Jennings P., Kisslinger.C. International Handbook of Earthquake and Engineering Seismology. Academic Press (2003).

- Sansei AIR Seismic Isolatio System CO., Ltd https://airdanshin.co.jp

- Abrams M. (2012, May 16). Made in Japan: Earthquake-Proof Homes. The American Society of Mechanical Engineers. https://www.asme.org/topics-resources/content/made-in-japan-earthquake-proof-homes

- Ali Khan M. Earthquake-Resistant Structures. Butterworth-Heimann (2013)

- BigRentz (2019, Feb 6) How Earthquake-Proof Buildings are designed Big Rentz https://www.bigrentz.com/blog/earthquake-proof-buildings

- Olayemi O. (2021 April 14) Materials used in Prefab Houses Matmarch https://matmatch.com/blog/materials-used-in-prefab-houses/

- Koshihara M. Creating Earthquake-Resistant Buildings Tansei10 https://www.u-tokyo.ac.jp/en/about/publications/tansei/10/75-recovery-buildings.html

- (2018, Feb 28). Earthquake Resistance of Buildings in Japan. Real State Tokyo https://www.realestate-tokyo.com/news/earthquake-resistance-of-buildings-in-japan/

- Gunawardena T., Mendis P. and Duc Ngo T. (2016, Dec). Behaviour of Multi-Storey Prefabricated Modular Buildings under seismic loads. Earthquakes and Structures. Vol. 11, No. 6, pp. 1061- 1076

- Vazquez Carazo A. and Uchino K. (2001, Dec). Novel Piezoelectric-Based Power Supply for Driving Piezoelectric Actuators Designed for Active Vibration Damping Applications. Micromachines. 12, 140

- Massey W., Megget L. Architectural Design for Earthquake. A guide to the design of non-structural elements. School of Engineering, University of Auckland (1989)

- Housner G. S., An historical view of Earthquake Engineering (1984)

Fig. 1. (2018, Feb 28). Earthquake Resistance of Buildings in Japan. Real State Tokyo https://www.realestate-tokyo.com/news/earthquake-resistance-of-buildings-in-japan/